Application Examples

Alternative Energy

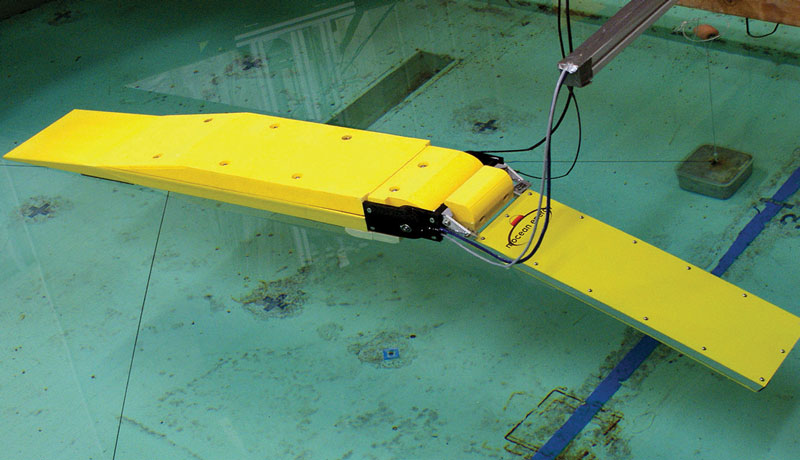

Mantracourt Helps Create Ocean Energy

This application demonstrates how the Strain Gauge Amplifer (SGA) was used in the Wave Energy Prize sponsored by the US Department of Energy.

In conjunction with Mantracourt’s Business Partner, Applied Measurements Ltd, they provided Mocean Energy with a complete torque measuring system for a 1/50th scale model wave energy converter.

The prototype was tested and evaluated in a wave tank with plans for a full scale version to convert wave force into electricity.

The SGA conditioned the torque sensor’s output signal into a high-level industry standard signal ready for integration to a data acquisiton system.

Key Benefits

Automotive

Mantracourt Takes Pole Position in Race Car Weighing

Find out how the T24 Wireless system saved time and improved accuracy in car set up

The world of motor racing is highly competitive and one of the keys to success is to manage and optimise the balance of the race car.

Mantracourt, a leader in high precision measurement electronics, through its French distributor Mantra France, has been working with the Sébastien Loeb Racing (SLR) team to supply a weighing system that would give their cars a competitive advantage.

Key Benefits

“The Mantracourt system was just what was required in terms of accuracy, reliability and repeatability. The service wereceived was excellent, with all engineers knowledgeable and helpful. We are delighted and the system has become a vital part of our race to success.”

-Jean Philippe Nicolao, SLR Team

Automotive

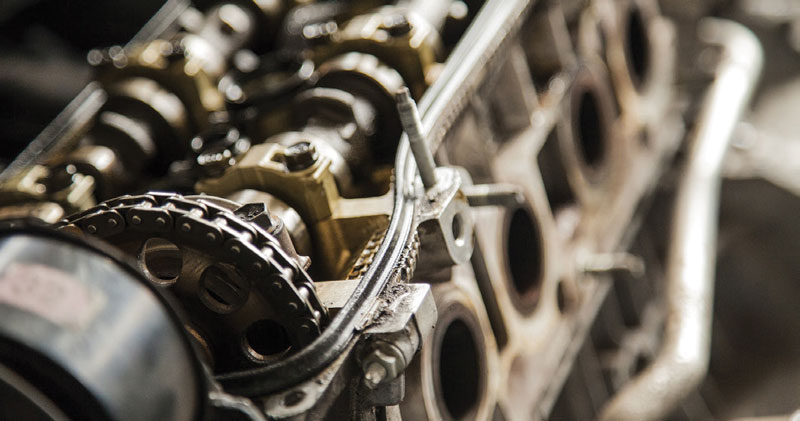

Measuring the Output Power of a Motor

A generator company were looking at a number of motors to potentially incorporate into their generator design. Each motor had rated power outputs but the company wanted to independently measure the power output of the various motors whilst in the generator housing, drawing various loads from the electrical supply. Mantracourt’s T24 range enabled the company to measure the torque on the shaft between the motor and generator windings and then multiply this by the RPM of the shaft.

In order to capture the torque, the shaft was fitted with an inline torque transducer; a T24-ACMI-SA strain acquisition module was calibrated to output the torque in Nm. The RPM of the shaft was captured using an optic sensor which created a pulse every time a white dot on the shaft passed the sensor; this sensor was coupled to a T24-ACMI-PA pulse acquisition module which calculated the RPM of the shaft. Rotation and temperature data were also captured.

Key Benefits